Retail space can be tight for many brands, making it difficult to get your product to stand out against competitors.

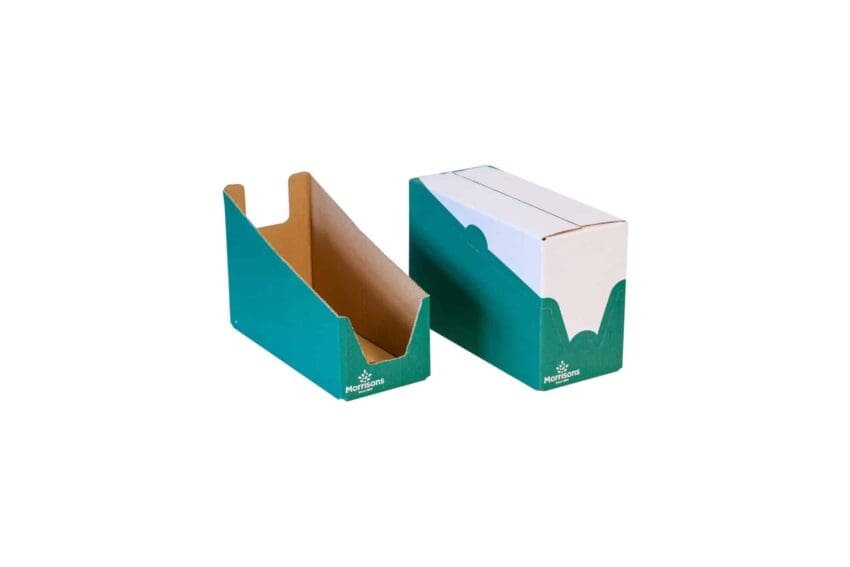

Shelf-ready packaging (SRP), also known as retail-ready packaging (RRP), is used to transport a product to retail stores and display the product once there. This is achieved using specially designed perforations and hoods so that part of the box can be removed by the retail staff, allowing the products to be displayed whilst still sitting in the base of the box. This means brands have yet another merchandising opportunity, giving them a chance to reinforce their brand image and encourage more sales with well-designed retail packaging.

The key to good shelf-ready packaging is to consider how both the retailer and the customers will see the box. But when you’re focused on getting your product out to the world, the packaging is often far down the to-do list.

At Colton Packaging, we help you choose an effective shelf-ready packaging design for your products. We also help you manage the packaging supply chain, ensuring you don’t run out of boxes, even in times of high demand.

Make your product stand out from across the store with attractive printed packaging that shows off your brand.

Make life easier for your retail partners with die-cut perforations that make the packaging simple to open, remove and dispose of.

To be shelf-ready, your product needs to remain intact during transit. Our packaging is designed to protect your product and look good while doing it.